UHMWPE liner,Wear resistant UHMWPE liner plate,UHMWPE sheets,engineering plastics,high performance Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com

A few days ago, details from the National Symposium on Special Equipment Safety Supervision were released. The Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) is currently working with various ministries, commissions, and geological inspection agencies to explore the implementation of energy-saving supervision for special equipment. This move marks a significant shift in focus from purely safety-based oversight to a more comprehensive approach that includes energy efficiency.

According to Zhang Gang, Director of the Bureau of Special Equipment at AQSIQ, in the past, local authorities primarily concentrated on the safety aspects of special equipment. However, there remains considerable potential for energy conservation and emission reduction within this sector. Moving forward, geological inspection departments will also be involved in energy-saving supervision, particularly for high-energy-consuming equipment.

Zhang emphasized that China is actively working on establishing a dual system that combines safety and energy-saving supervision. This initiative aims to drive national efforts in energy conservation and resource efficiency. The goal is not only to ensure the safe operation of equipment but also to reduce energy consumption across industries.

Looking ahead, China plans to implement energy-saving measures for special equipment through several key areas. First, it will improve existing laws and regulations related to energy conservation. Second, it will enhance energy-saving monitoring during the operational phase of equipment. Third, it will promote energy-saving upgrades in critical industries and enterprises, especially for high-consumption equipment like boilers.

Additionally, the government will invest in research and development of energy-saving technologies for special equipment, aiming to foster innovation and long-term sustainability. These steps are part of a broader strategy to support environmental protection and achieve national energy goals.

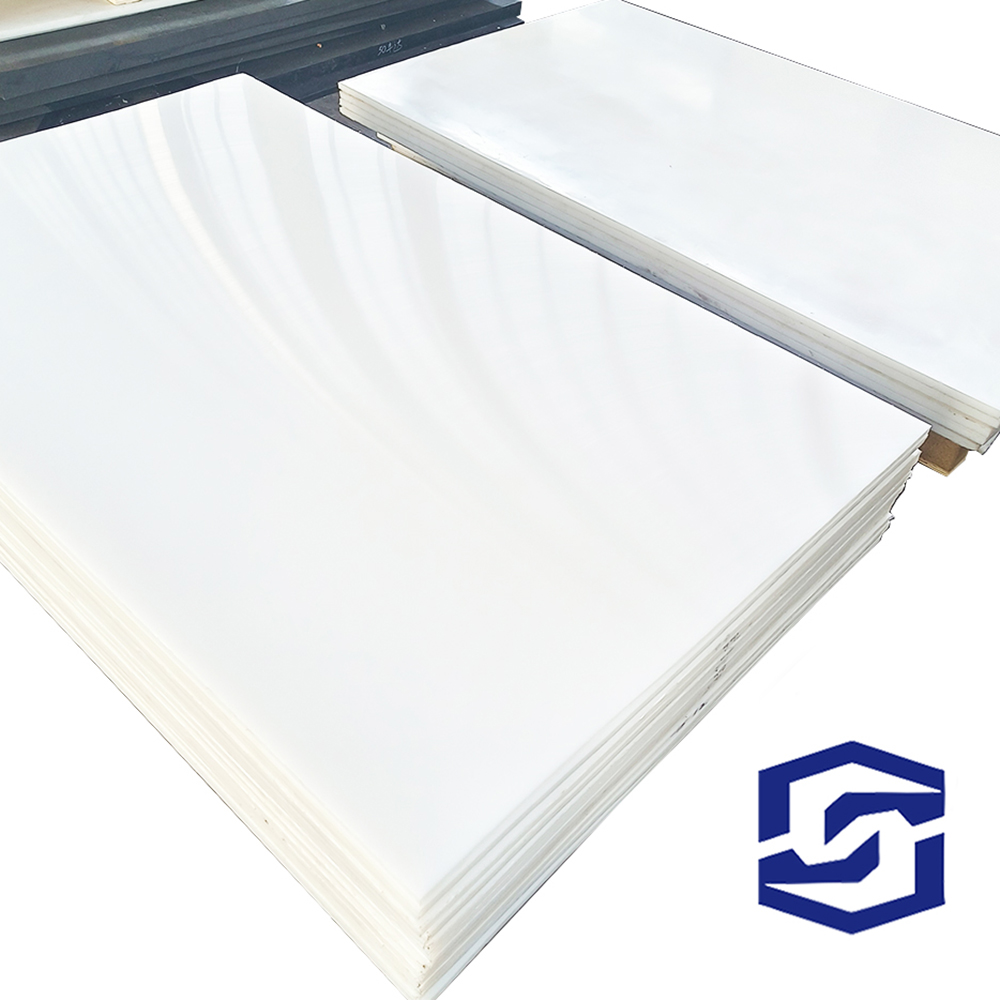

Ultra-high molecular weight polyethylene linerboard also known as UHMWPE liners, is a thermoplastic engineering plastics with molecular weight up to more than 3 million, it has good anti clogging, self-lubricating, non absorbent, high wear resistant, corrosion resistant, it has been widely used in coal, electric power, cement, metallurgy, and other industries in the raw coal silo, clay silo, iron silo, mixing silo, and other kinds of silos.

The product can completely solve the silo, hopper, mine chute, chute, storage boxes and other warehouse wall of the sticky material, stick to the wall, blocking material and other serious impact on the production of the problem.

Â