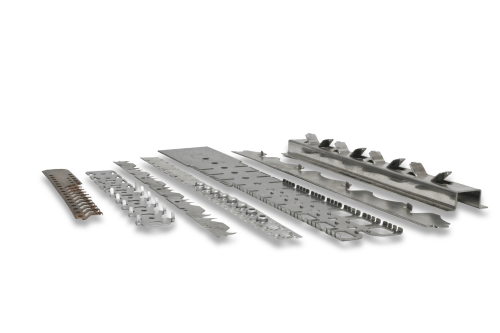

Progressive die stamping is a highly efficient manufacturing process used to create complex metal parts with high precision and consistency. It involves feeding a continuous strip of metal through a series of stations within a progressive die, where each station performs a specific operation—such as cutting, bending, or forming—to gradually shape the material into the final part. This method allows for mass production at high speeds while maintaining tight tolerances, making it ideal for industries that require durable, repeatable components. The progressive die stamping process typically consists of four main stages: Discover our in-house tool and die manufacturing capabilities This process ensures ultra-high precision at every stage, making it suitable for critical applications across various industries. Let’s take a closer look at the key steps involved in creating these high-quality parts. The process begins with designing the stock strip using advanced computational modeling. Engineers optimize the layout of punches, bends, and holes to ensure accuracy and efficiency in the final product. Once the design is complete, CNC machining is used to produce the die blocks with exact specifications. These parts undergo rigorous quality checks before being used in production to ensure consistent performance. Parts are strengthened through heat treatment, which increases their hardness and dimensional stability. Grinding may also be applied to achieve even higher levels of accuracy and surface finish. Wire electrical discharge machining (EDM) is used to create intricate shapes with extreme precision. This process can achieve tolerances as tight as ±2 µm and surface finishes as low as Ra 0.1 µm. All die components are assembled according to the original design using precision instruments to ensure proper function and durability. The die is installed in a stamping press, and the metal strip is fed through, undergoing multiple operations per press stroke until the part is fully formed. Once the parts are produced, they are packaged using automated systems to ensure accuracy and efficiency in delivery. Many industries depend on progressive die-stamped parts, including automotive, medical, aerospace, and consumer goods. These parts are essential due to their durability, precision, and ability to be produced in large volumes quickly. Read More: Progressive vs. Fourslide vs. Traditional Power Press Stamping ESI has provided innovative solutions for many industries, including: At ESI, we continuously invest in new technologies to improve quality and reduce costs for our customers. With over 30 years of experience in metal stamping and mission-critical parts, we are dedicated to delivering exceptional results. To learn more about how we can help with your tool and die needs, contact us or request a quote. Small Forklift Price,Small Electric Forklift,Mini All Terrain Forklift,Small Electric Forklift For Sale Shandong Yineng Heavy Industry Co.,Ltd , https://www.yinengloader.com

Understanding the Progressive Die Stamping Process

How Parts Are Made Using Progressive Die Stamping

Stock Strip Layout & Design

Tool Steel and Die Set Machining

Secondary Processing: Grinding & Heat Treating

Wire EDM

Die Assembly

Stamping the Parts

Packaging and Shipping

Industries That Rely on Progressive Die Stamping

Our Progressive Die Stamping Services

Comments are closed