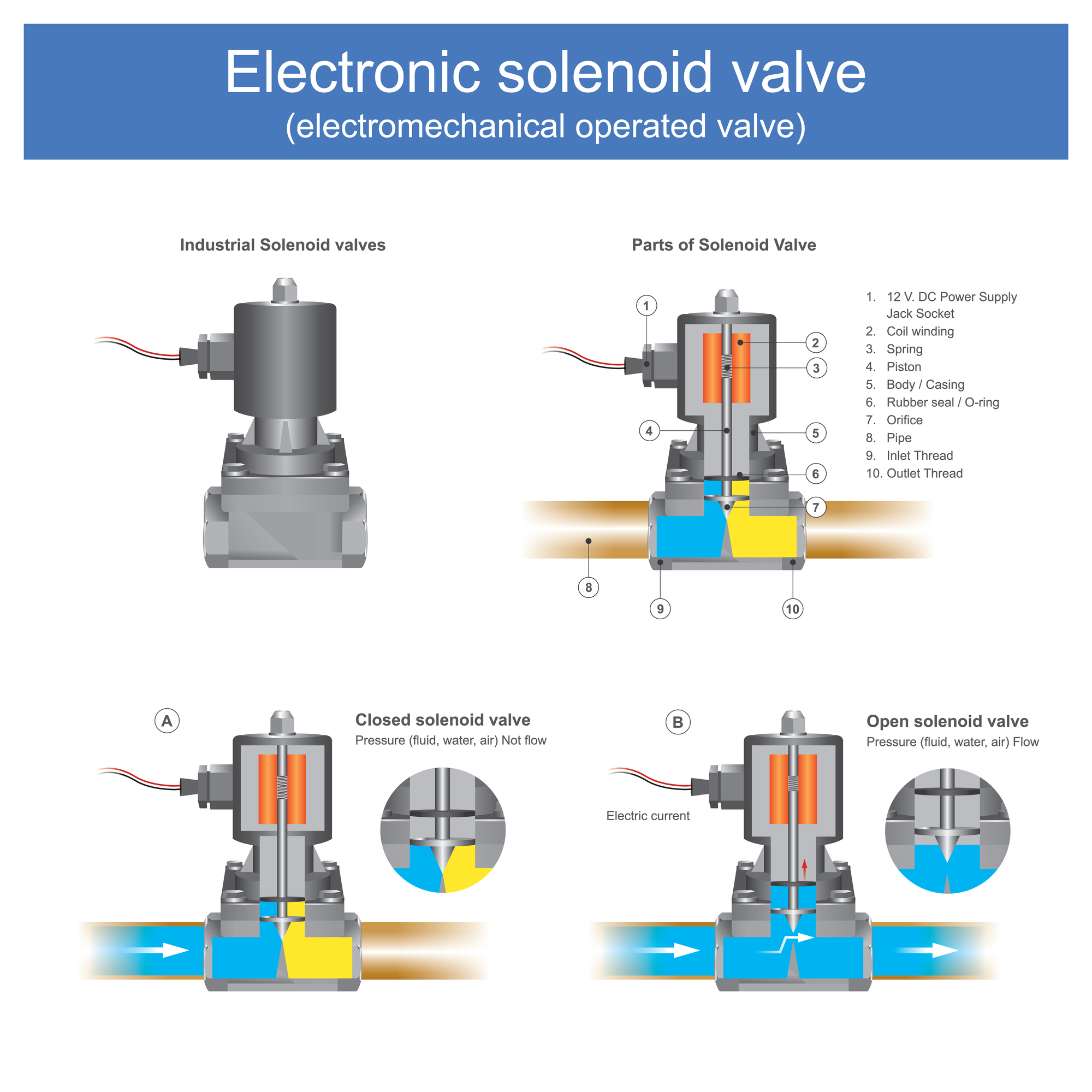

Brewing is an intricate process where every detail contributes to the final product's quality. Among the many components involved, solenoid valves play a vital role that is often underestimated. These small but powerful devices are essential in controlling and maintaining the flow of liquids throughout the brewing cycle, ensuring efficiency, consistency, and safety. Solenoid valves are crucial for managing the movement and flow rate of liquids during brewing. Their accuracy and dependability make them indispensable in various stages of the process. As brewing technology continues to evolve, the push for greater efficiency and consistency has led to significant improvements. At the core of this transformation are innovations like automated systems, which rely heavily on solenoid valves. Choosing the correct solenoid valve is essential for any brewing operation. It depends on specific needs such as flow rate, size, and material compatibility. In the complex art of brewing, even the smallest components can have a big impact. Solenoid valves, though often overlooked, are central to managing liquid flow and quality. They directly affect the efficiency, safety, and consistency of the brewing process. For breweries aiming to improve their performance, investing in the right solenoid valves is not just a technical choice—it's a step toward excellence in every batch of beer produced. Answer: Yes, indirectly. By ensuring precise control over liquid flow and temperature, solenoid valves help maintain consistency throughout the brewing process. This consistency plays a key role in preserving the intended flavor profile of the beer, leading to a more predictable and high-quality final product. Answer: A solenoid valve is an electromechanical device used to control the flow of liquids. In brewing, it operates by opening or closing in response to an electric signal. This allows for accurate regulation of liquid flow, such as water or wort, during different stages of the brewing process. This precision helps maintain consistent flavor and quality from one batch to the next. Tungsten alloys rods are made from a mixture of tungsten and other metals such as nickel, copper, and iron. These alloys have high density, high melting point, and excellent mechanical properties, making them ideal for use in various applications. Tungsten Alloy Rod,Tungsten Alloys Swaging Rod,Tungsten Heavy Alloy Darts Zhuzhou Jiuding Metal Technology Co., Ltd. , https://www.zztungstenheavyalloy.comIntroduction

Precision in Liquid Handling

Selecting the Right Solenoid Valve

Conclusion

Frequently Asked Questions:

Can the use of solenoid valves impact the taste of the beer?

What is a solenoid valve and how does it work in brewing?

Tungsten alloys rods are commonly used in the aerospace industry, as they have excellent radiation shielding properties and can withstand high temperatures. They are also used in the medical industry for radiation therapy and in the automotive industry for balancing weights.

The composition of tungsten alloys rods can vary depending on the specific application. For example, a high-density tungsten alloy rod may contain 90-97% tungsten, while a radiation shielding tungsten alloy rod may contain 90-95% tungsten, 3-5% nickel, and 1-2% copper.

Tungsten alloys rods are a versatile and reliable material that can be used in a wide range of industries and applications.