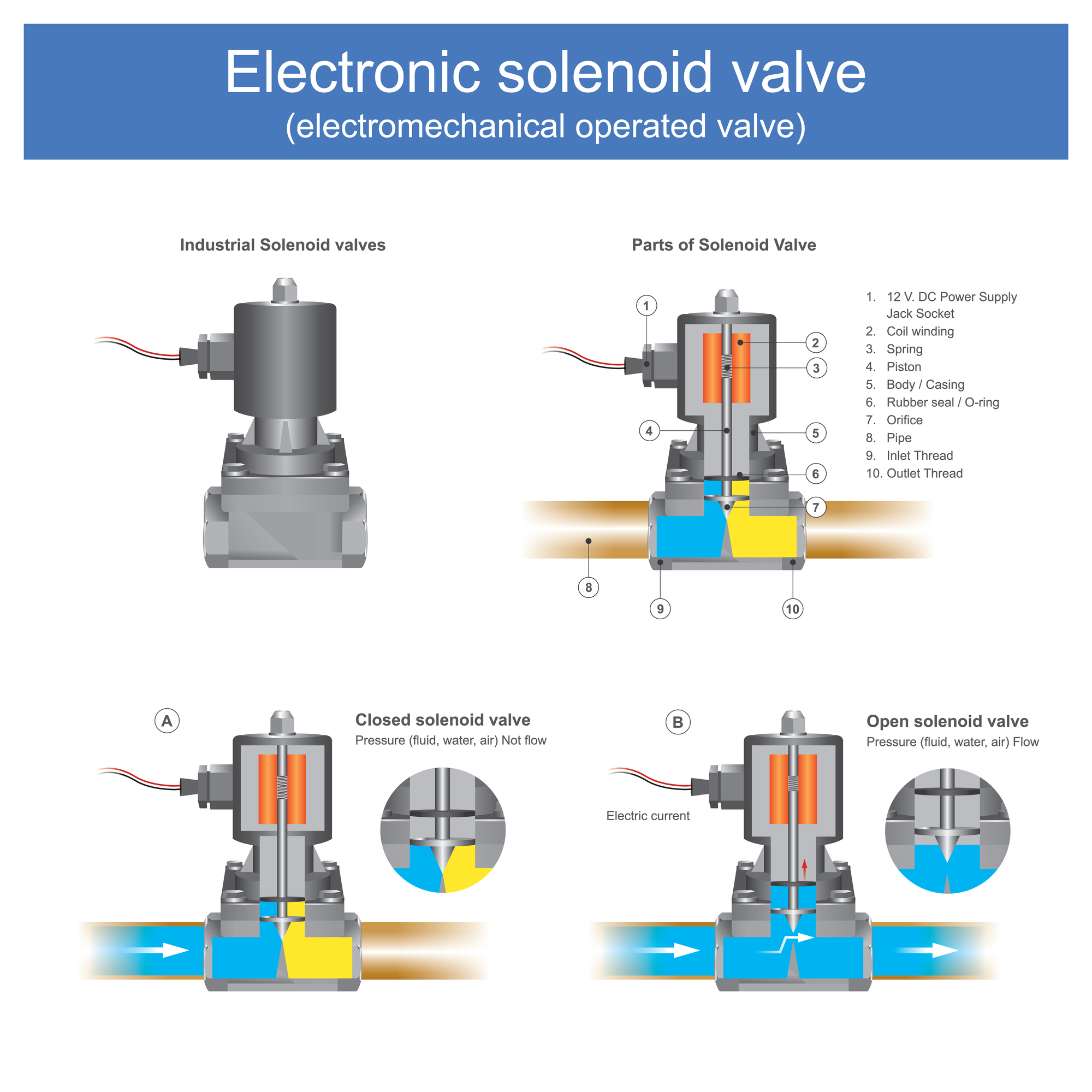

Brewing is a complex and delicate process where every detail matters. From the selection of ingredients to the final packaging, each step contributes to the overall quality of the beer. Among the many components involved, solenoid valves often go unnoticed but play a vital role in ensuring smooth and precise liquid handling throughout the brewing cycle. These small but powerful devices are essential for maintaining control over liquid flow, temperature, and pressure—key factors that influence the consistency and flavor of the final product. Whether you're a homebrewer or part of a large-scale brewery, understanding the importance of solenoid valves can make a significant difference in your operations. Solenoid valves are critical tools for managing the movement and flow rate of liquids in brewing. Their ability to respond quickly and accurately makes them ideal for a variety of applications, from ingredient dosing to temperature regulation. As brewing technology continues to evolve, the need for precision and efficiency has never been greater. One of the most impactful developments in recent years has been the rise of automated brewing systems, which rely heavily on solenoid valves to streamline operations and improve consistency. Choosing the right solenoid valve is essential for the success of any brewing operation. Not all valves are created equal, and the wrong choice can lead to inefficiencies or even equipment failure. In the world of brewing, even the smallest components can have a big impact. Solenoid valves may seem simple, but their role in controlling liquid flow, temperature, and automation is indispensable. Whether you're aiming for better efficiency, safer operations, or more consistent flavors, investing in the right solenoid valves is a smart move for any brewer. By focusing on precision and reliability, breweries can elevate their craft and deliver a superior product that stands out in a competitive market. It’s not just about the ingredients or the recipe—it’s also about the tools that bring it all together. Answer: Yes, indirectly. By providing precise control over the flow and temperature of liquids, these valves ensure consistency in the brewing process, which is crucial for maintaining the intended flavor profile of the beer. Consistent temperatures and ingredient mixing lead to a more reliable and high-quality end product. Answer: A solenoid valve is an electromechanically operated device used to control the flow of liquids. In brewing, it works by opening or closing in response to an electric signal, allowing for accurate control of liquid ingredients like water, wort, and additives. This level of precision helps ensure uniformity in each batch of beer, contributing to better quality and consistency. Tungsten FDG Contanier for nuclear medical Tungsten Alloy Shielding for radioactive nuclide injection is a device used to protect medical personnel and patients from radioactive nuclide radiation. It is made of tungsten alloy, which can effectively shield the radiation of radioactive nuclides while maintaining the flexibility and operability of the syringe. Tungsten alloy shielding can reduce the radiation dose of radioactive nuclides during the injection process, thereby reducing the radiation risk for medical personnel and patients. In addition, tungsten alloy shielding also has corrosion resistance and wear resistance, which can be reused and reduce the cost of medical equipment. Tungsten FDG contanier,Tungsten Container Shielding,Tungsten Alloy Radiation Cover,Hospital Medical Radiation Shielding Zhuzhou Jiuding Metal Technology Co., Ltd. , https://www.zztungstenheavyalloy.comIntroduction

Precision in Liquid Handling

Selecting the Right Solenoid Valve

Conclusion

Frequently Asked Questions:

Can the use of solenoid valves impact the taste of the beer?

What is a solenoid valve and how does it work in brewing?