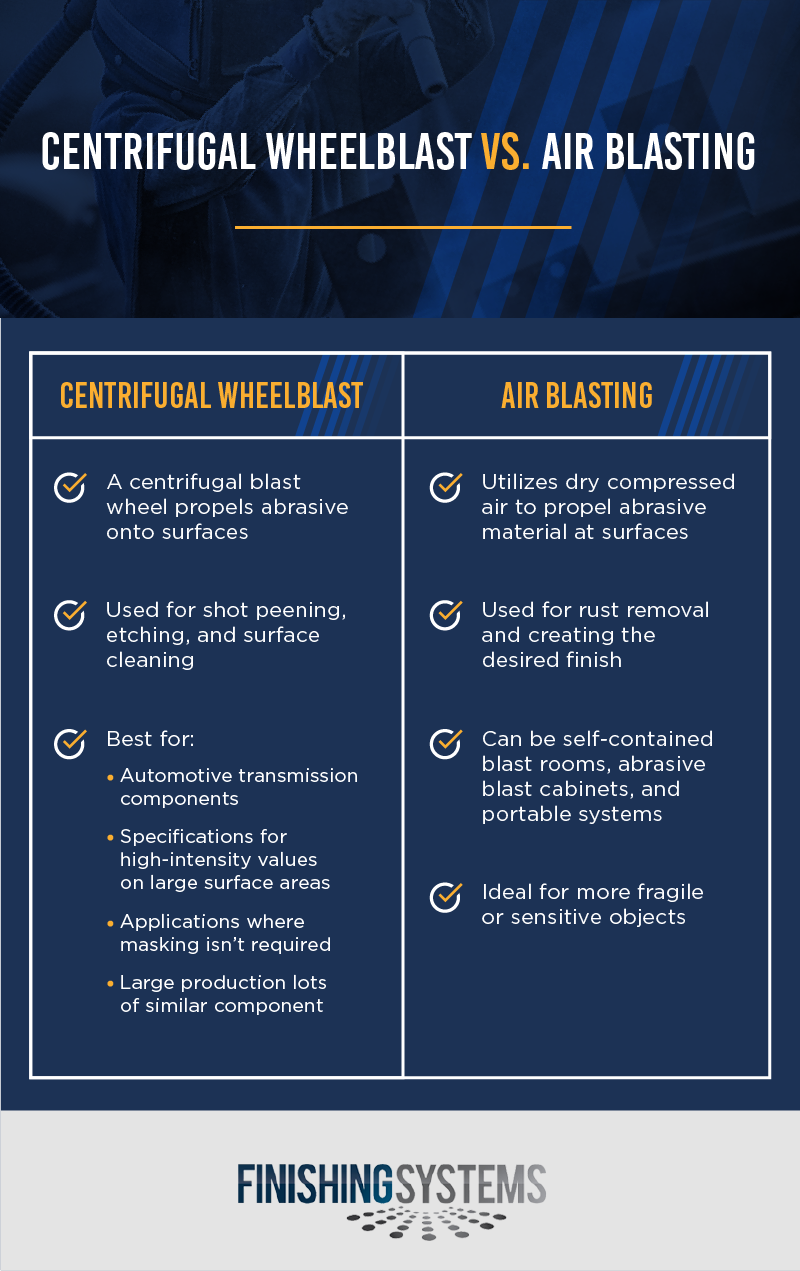

Deciding between abrasive blasting methods can feel overwhelming, especially when you're weighing options like wheel blasting versus air blasting. Both techniques aim to clean, descale, or finish metal components, but they do so in very different ways. Choosing the right method depends on factors such as the size, shape, and quantity of your parts, along with the specific outcome you're aiming for. Ensuring you select the correct equipment, cycle settings, and media ensures that your parts get the desired finish efficiently and cost-effectively. With numerous blasting materials and methods available, picking the best one requires careful consideration. If you're torn between wheel blasting and air blasting, this guide should help clarify which option aligns with your needs. For expert advice tailored to your project, reach out to us today. In wheel blasting, a centrifugal blast wheel propels abrasive media onto the surface of your parts. This method is ideal for tasks like shot peening, etching, and surface cleaning. Compared to air blasting, wheel blasting moves significantly more abrasive across the part's surface at once. The blast wheel itself can be direct-driven or belt-driven via a bearing system, with the speed and power directly influencing the cycle time. Modern VFD (variable frequency drive) models allow you to adjust the wheel speed for precise control. Wheel blasting is particularly well-suited for scenarios involving: Typically, you load your parts into the wheel blast machine's chamber, where the abrasive is introduced. The blast wheel uses centrifugal force to apply an even coating of abrasive across all surfaces. This makes it ideal for processing large quantities of small items or fewer, larger ones. Short cycle times ensure rapid completion of the process, and metallic abrasives like steel shot or aluminum cut wire work exceptionally well here. Air blasting relies on compressed air to accelerate abrasive particles toward the surface of your parts. A reliable supply of compressed air is crucial for optimal performance. Through nozzles, the air propels the abrasive toward the target surface, making it suitable for everything from rust removal to achieving specific finishes. Air blasting systems come in various configurations, including self-contained blast rooms, enclosed cabinets (both direct-pressure and suction types), and portable units. Effective dust collection is vital for maintaining visibility and cleanliness within these setups. When comparing wheel blasting and air blasting, understanding their strengths can guide your decision-making. Wheel blasting excels in speed, efficiency, and handling large objects. Its broader coverage allows for faster treatment of expansive surfaces. Additionally, it tends to be more economical for larger components. However, air blasting offers precision, especially when dealing with delicate or intricate parts. Direct-pressure cabinets provide finer control over the blast stream, allowing for customization of the finish based on the chosen abrasive. Ultimately, the choice hinges on your specific requirements. For robust, high-throughput projects, wheel blasting stands out. Conversely, air blasting shines in applications demanding gentle handling or complex geometries. Still undecided? Or perhaps you're ready to invest in new equipment? Finishing Systems is here to help. Our extensive range of blasting and finishing solutions ensures you'll find the perfect setup for your goals. Whether you need advice on media selection or equipment installation, our team is ready to assist. Get in touch with us today to discover how we can support your project!

The grinder is composed of a moving disk and a gear ring. Through the high-speed rotation of a special shape of the moving disk, it is squeezed, collided and cut for many times, so as to achieve crushing. The material receives impact and shear between the high-speed rotating rotor and the stator of the toothed lining. The crushed material enters the grading area driven by the air flow. The qualified material is collected by the cyclone and dust collector, and the unqualified material is returned to the crushing area for crushing.

â— The machine has compact and reasonable structure, small size, low energy consumption, high efficiency, stable speed, low noise, reliable sealing, no dust pollution, simple installation, easy disassembly and repair, convenient replacement of damaged parts;

â— The equipment adopts the specialty of domestic and foreign dry mechanical crusher, according to the need to use large air volume into the cavity or water jacket cooling, in order to reduce the crushing heat, to prevent the shortcomings of material particles sticking to the wall, sticking to the crushing surface;

The machine also has a self-cooling function, especially active abundant hand processing thermoplastic, fibrous material use and chemical heart medicine, seasoning, paint, pigment, dye, feed, plastic, carbon black, Catalyst, aluminum hydroxide, alumina, talc, mica, graphite, AC foaming agent, petroleum coke, pesticide, dye, coating, flame retardant, carbon black, electronic materials, rubber, metallurgy, ceramics, food, building materials, ore, cement, refractory materials, inorganic minerals, cereals and other ideal equipment for crushing.

Ultrafine Impact Grinder,Superfine Impact Pulverizer,Superfine Impact Mill Shandong Jing Xin Powder Equipment Technology Co., Ltd. , https://www.jxpowder.comCentrifugal Wheelblast vs. Air Blasting: Which One Fits Your Needs?

Last Updated: October 17, 2023

Understanding Wheel Blasting

Exploring Air Blasting

Making the Right Choice

Partner with Finishing Systems for Expert Guidance