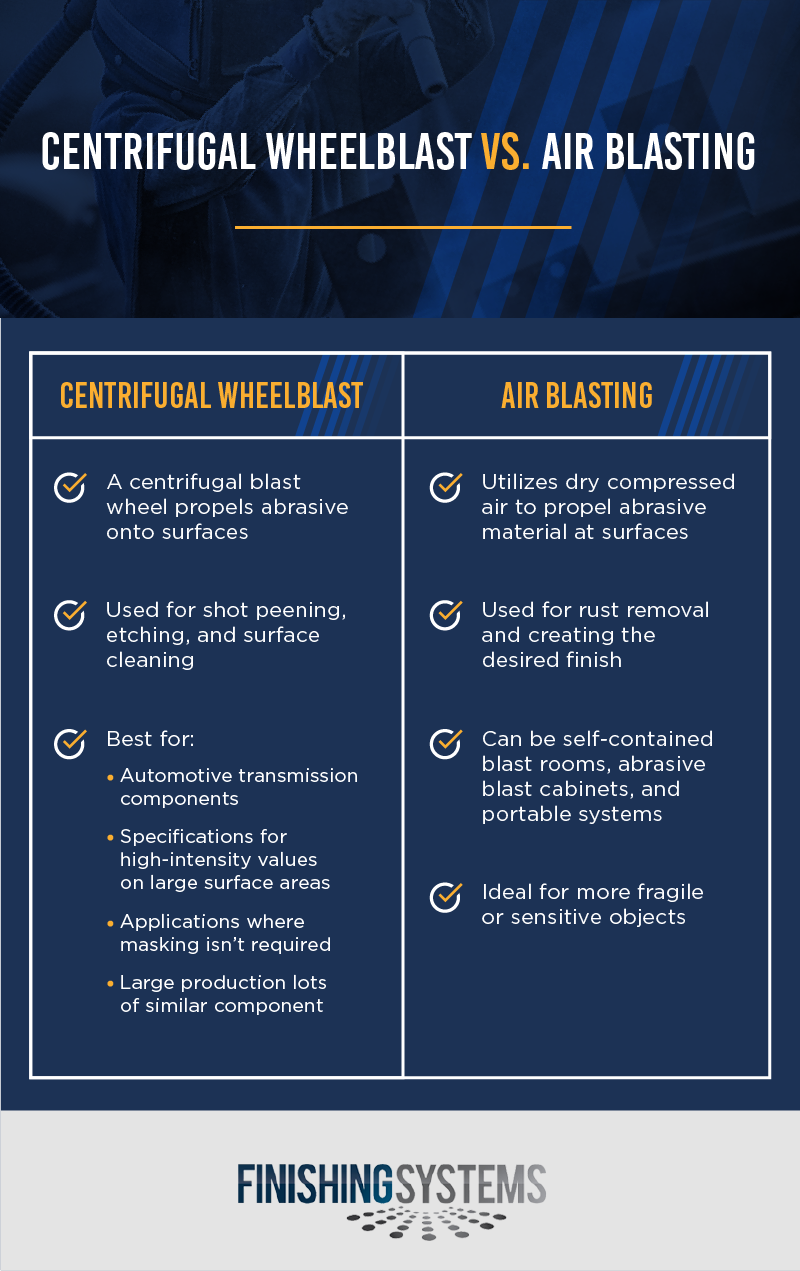

Are you torn between choosing centrifugal wheelblasting or air blasting for your project? Both techniques involve propelling abrasive media onto the surface of a metal component to descale, etch, peen, or clean your parts. The size, configuration, and quantity of your components often play a critical role in determining which method is best suited to meet your specific requirements. Selecting the right equipment, process cycle, and abrasive ensures optimal results at the lowest possible cost and with maximum efficiency. Given the vast array of blasting materials and methods available, selecting the ideal solution can feel overwhelming. If you're trying to decide whether to go with wheel blasting or air blasting, this guide should help clarify things for you. For expert advice tailored to your needs, don't hesitate to reach out to us! Wheel blasting systems rely on a centrifugal blast wheel to hurl abrasive particles toward the surface of your parts. This approach is commonly used for tasks like shot peening, etching, and surface cleaning. Compared to air blasting, wheel blasting systems operate with a significantly higher volume of abrasive media, enabling faster processing speeds. Centrifugal blast wheels are typically direct-driven or belt-driven through a bearing system. The speed of the blasting cycle directly correlates with the wheel's rotational speed and power output. Modern VFD (variable frequency drive) models allow users to adjust the wheel's speed for greater flexibility. Wheel blasting is particularly well-suited for applications involving large quantities of similar components and high-intensity surface treatments over expansive areas. Key advantages include: In a typical wheel blasting setup, abrasive media is loaded into the machine, followed by the placement of your parts inside the blast chamber. The blast wheel then uses centrifugal force to deliver an even distribution of abrasive across all exposed surfaces. This method works exceptionally well for metallic abrasives such as steel shot or grit, zinc or aluminum cut wire, and stainless steel shot or grit. Air blasting, on the other hand, employs compressed air to propel abrasive materials toward the target surface. To ensure smooth operation, an ample supply of compressed air is essential. In this setup, abrasive media is expelled through a nozzle directed at the workpiece. Air blasting finds application in diverse fields, ranging from rust removal to achieving specialized finishes. Air blast systems come in various configurations, including standalone blast rooms, portable units, and enclosed cabinets—both direct-pressure and suction types. Effective dust collection within these systems maintains a clean workspace and improves visibility during operations. Deciding between wheel blasting and air blasting ultimately depends on your specific needs. Wheel blasting excels in terms of speed, efficiency, and handling larger items. However, for delicate or intricate components, air blasting offers finer control over the blasting process. Direct-pressure air blasting cabinets, for instance, provide precise regulation of blast pressure, allowing for customized finishes based on the chosen abrasive material. When working with fragile or sensitive objects, air blasting proves advantageous due to its localized impact. By adjusting factors like nozzle size, angle, and abrasive type, you can achieve a wide range of finishes, from coarse to fine. Still unsure which method suits your requirements? Or perhaps you're considering installing new equipment? Look no further than Finishing Systems. Our comprehensive selection of blasting and finishing solutions, coupled with a broad range of blast media options, ensures you'll find the perfect combination to achieve your desired outcome. Ready to take the next step? Contact us today to discuss your requirements and discover how we can support your project.

â—† Fine chemicals, ceramics, abrasions and refractorials] Typical materials are: garnet silicon carbide, corundum, cerium oxide, alumina, boron carbide, tungsten carbide, emery, etc.

â—† Food, medicine and health care products] Typical materials are: pollen, hawthorn, pearl powder, stomach medicine, nimodipine, antibiotics, contrast drugs, Ganoderma lucidum, Gallnut, multiflorum multiflorum, etc. :

â—†Magnetic powder, mobile phone electromagnetic powder, photocopying toner and electronic materials Typical materials are: lead battery, nickel-chromium battery, nickel-manganese battery, ferrite, manganese tetroxide, manganese dioxide, lithium cobalt, lithium manganate, carbon, etc.

â—† Non-metallic ore and powder metallurgy] Typical materials are: quartz, barite, kaolinite, high calcium, talc, mica, graphite, wollastonite, etc.

â—† Reflective materials, pigments, dyes and powder coatings] Typical materials are: iron oxide, titanium dioxide, glass beads, etc. :

â—† Pesticide, feed and biological materials

Inverted classifier,handstand classifier,headstand classifier,fine grade air classifier,food and pharmaceuticals air classifier Shandong Jing Xin Powder Equipment Technology Co., Ltd. , https://www.jxpowder.comCentrifugal Wheelblast vs. Air Blasting: Which Is Right for You?

Last Updated: October 17, 2023

Understanding Wheel Blasting

Exploring Air Blasting

Making the Right Choice

Partner with Finishing Systems for Expert Guidance