Our conversation with Amanda Smith, the UAV equipment program manager at Sellafield, delves into how drones are utilized on-site and the ways they enhance safety. Her insights highlight the transformative role drones play in managing one of the most complex decommissioning projects in the world. Sellafield, previously known as Windscale, is a sprawling site along the Cumbrian coast in the UK. While it ceased operating as an active nuclear power plant in 2003, it remains home to an extensive decommissioning project, one of the largest globally, expected to span decades. The scale of this endeavor makes Sellafield a unique case study in adapting modern technology to legacy infrastructure challenges. Amanda Smith leads the UAV equipment program at Sellafield, a division within the broader Engineering and Maintenance Profession. With a workforce of 3,500 employees, Sellafield manages a diverse array of projects, including the development of innovative tools like drones. Amanda shared her journey in spearheading this initiative and how drones contribute to achieving the site's core objectives—working more safely, efficiently, and cost-effectively.  I've been overseeing the UAV program at Sellafield for nearly four years. Before this role, I had no hands-on experience with drones. However, our team recognized the potential value drones could bring to our operations. My background is in electrical engineering, so transitioning into drone technology was quite the learning curve. Yet, we’ve come a long way since those early days. Today, we conduct routine flights, and drones have become an indispensable tool for inspections. We’re also exploring advanced applications, such as using drones for radiation detection. To give you an idea, Sellafield resembles a small town—it covers almost six square kilometers. It houses its own fire department, medical services, and numerous departments spread across the site. Sellafield is one of 17 sites under the Nuclear Decommissioning Authority (NDA), a government initiative tasked with cleaning up the UK's early nuclear facilities. Other sites within the NDA have their own drone programs, and we collaborate to share best practices and address common challenges. This collaboration has enabled us to support drone operations at other locations, such as Bradwell in Essex and Sizewell in Suffolk. As part of my role with Sellafield, I evaluate emerging technologies and assess their applicability to our operations. We don't just focus on the technology itself but also on the companies behind it, ensuring future products align with our needs and goals. Our initial experiments with drones at Sellafield involved contracting an external provider to introduce us to drone operations. After evaluating potential use cases, we decided to establish an in-house program. Given the novelty of the technology, it took six months to secure clearance and execute our first flight. We developed rigorous processes, adhered to safety protocols, and obtained approvals from various departments and leadership teams. Our initial missions focused on security and resilience response. By 2020, the program began to expand, and in 2021, we conducted over 200 asset inspection flights. Today, our drone fleet comprises more than 20 drones operated by around 20 certified pilots. Currently, I oversee a team of four equipment engineers who double as remote pilots. They possess deep expertise in our drones, handling everything from research and selection to testing and maintaining them. Each drone undergoes meticulous maintenance schedules, with checks at intervals of three, six, and twelve months. Additionally, we maintain an emergency duty team with on-call personnel available around the clock, even during holidays. Annually, our core team completes at least 200 flights. Initially, drones were primarily used for external inspections, but we're now witnessing a surge in internal inspections. Outputs include visual inspections, 3D models, and LiDAR scans. With the Elios 3 RAD payload, we’re exploring further possibilities through ongoing testing and proof-of-concept flights. Operating in radioactive or contaminated environments presents several challenges. Two key concepts to understand are radiation and contamination. We encounter both contamination and newly radioactive materials regularly. Contamination poses a greater challenge because it means we cannot remove equipment from a contaminated area unless it can be proven that every surface has been thoroughly decontaminated. "Loose contamination," or contaminated dust, is particularly problematic. While we can clean dust off the propellers or cage of an Elios drone, accessing the insides of the motors to ensure they are free of contamination is impossible. Therefore, once a drone enters a contaminated area, it remains there permanently. We can still perform battery replacements, collect data, and conduct necessary maintenance, but all activities must occur within the contaminated zone. However, there are limitations to using drones in areas with significant amounts of loose contamination. When a drone flies, it naturally stirs up the air, potentially moving this loose contamination. While some environments allow for this, there are strict guidelines regarding the accumulation of loose contamination. If there’s a risk that the drone could disturb dust in a way that exceeds regulatory limits, we avoid using drones in those spaces. The RAD payload is a specialized attachment for the Elios 3 drone, designed for remote radiation detection and localization. It features an RDS-32WR sensor by Mirion Technologies. Our proof-of-concept flight aimed to assess how the Elios 3 and RAD payload could detect changes in radiation levels during radiological surveys. We created a test setup spanning multiple rooms, placing known sealed sources alongside "dummy" sources to prevent confirmation bias. A pilot then flew the Elios 3 equipped with the RAD payload, identifying radiation spikes to generate a "radiation heat map" of the space. This initiative involved collaboration among my team, the radiometrics systems group, and representatives from Flyability and Coptrz. Early results indicate success! The RAD payload successfully detected elevated radiation levels and pinpointed a particularly strong sealed source in a separate room. The pilot could then investigate further. Following this initial success, we plan to conduct additional tests to optimize flight techniques for data collection. We’ll also evaluate the sensor’s performance across various environments to establish clear use-case profiles. Our Elios drones already support a wide range of projects. The RAD payload is especially promising, aligning perfectly with our strategic goals of enhancing safety, speed, and cost-efficiency. Safety is enhanced by enabling drones to conduct preliminary surveys, testing radiation levels before human entry or accessing contaminated zones swiftly. This minimizes unnecessary personnel exposure, freeing up resources for higher-priority tasks. Deployment speed is another advantage. Our drones can be launched rapidly, with pilots always on call. Using drones for safety inspections streamlines processes, and pre-scouting areas improves situational awareness. Data is immediately available, empowering quick decision-making. Cost savings are realized through multiple channels. For instance, deploying drones instead of scaffolding for high-access inspections saves significant time, money, and labor. Before integrating the RAD payload, UAVs were already helping us save approximately £5 million annually compared to traditional methods. We’re discovering diverse applications for Elios drones. Our fleet includes the original Elios model, Elios 2, and Elios 3. Internal inspections are increasing, particularly with the Elios 3’s LiDAR scanner. A typical inspection might involve using an Elios drone to examine pipe hangers, which safeguard and suspend critical infrastructure, including chemical and radioactive material transport. Maintaining these systems is crucial for safety, and drones provide vital visual insights to guide maintenance efforts. Elios drones also excel in inspecting tall, hard-to-reach assets like crane elements, which traditionally require scaffolding. This reduces safety risks and saves time. The protective cage ensures safe proximity to assets, preventing crashes that could render standard drones unusable. We'll continue expanding our use cases. Initially reactive and responsive, we're now routinely conducting inspections. Observers often suggest new applications after witnessing drone capabilities, leading to broader scopes of work. The modular design of the Elios 3 is particularly exciting. We're testing the RAD payload now, but the LiDAR payload is already generating interest. A recent LiDAR inspection produced a point cloud being used to create a 3D-printed model of a specific site element. In terms of fleet growth, we're continuously training pilots. They master drone operation and equipment specifications inside and out. Optimizing flight techniques enhances our operations. While specifics remain confidential, UAVs consistently help us achieve safer, faster, and cheaper operations. A heartfelt thank you to Amanda Smith and Tom Calverley for participating in this interview and sharing their experiences. For more information, visit the UK Government page on Sellafield. Learn more about the Elios 3 and its applications here. Electric Aroma Diffuser,Electric Diffuser Air Freshener,Smart Home Fragrance Diffuser,Best Room Fragrance Diffusers Guangzhou Chiyang Scent Technology Co., Ltd. , https://www.diffuserscent.comInterview: Elios Drones at Sellafield, Europe's Largest Nuclear Site

Tell Us About Your Background. Did You Work With Drones Prior To Starting The Sellafield UAV Program?

Tell Us About Sellafield – What Are You Doing There?

How Would You Describe The Sellafield UAV Programme?

How Are You Using Drones In Radioactive Or Contaminated Environments? We've Heard About Radioactive Dust – Could You Tell Us More About That And What Challenges You Face?

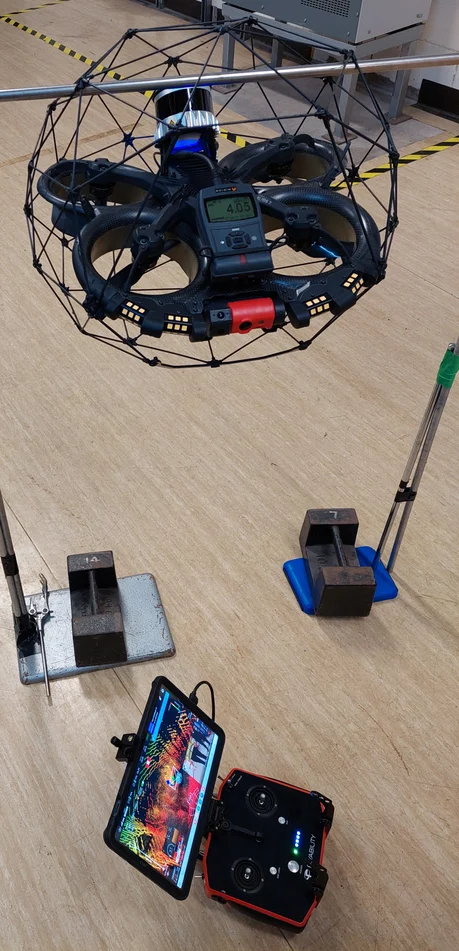

You Have A Substantial Fleet Of Elios Drones From Flyability. This Year, We Launched The Elios 3 Drone Along With The RAD Payload Specifically For Use In The Energy Industry. In July 2023, You Had A Proof Of Concept For This Payload. What Was The Process?

What Are Your Thoughts On Working With Elios Drones In These Use Cases?

The Elios 3 RAD in testing at SellafieldSo, What's Next For Your Drone Fleet At Sellafield?