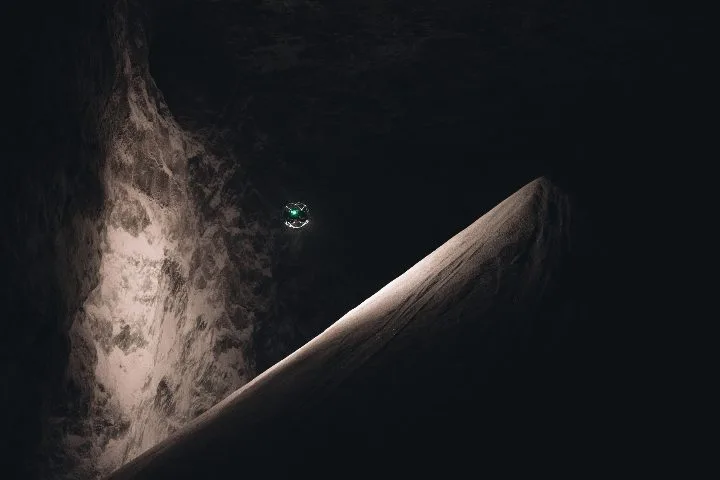

At a salt mine in Germany, mining engineers have successfully used the Elios 3 drone equipped with LiDAR technology to measure stockpiles, significantly improving both safety and accuracy in their operations. Speed Traditionally, calculating the volume of salt stockpiles was a laborious task that required surveyors to physically climb the piles. The Elios 3 allows them to stay on the ground while capturing high-resolution data quickly, dramatically reducing the time needed for each survey. Accuracy The 3D models generated by the Elios 3 offer a level of precision that manual methods simply can’t match. This leads to more reliable data, helping the mine better manage its inventory and optimize resource planning. Safety Climbing large salt piles is dangerous and physically demanding. By using the Elios 3, surveyors eliminate the risk associated with working at heights, making the entire process safer and less strenuous. Volume calculations are a routine but critical part of mining and aggregate operations. They help track material levels, plan backfilling, and ensure efficient resource management. However, traditional methods are often slow, inaccurate, and unsafe. Surveyors typically climb stockpiles to take measurements, which is not only time-consuming but also poses risks. In storage areas, handheld sensors and truck weighments are used, but these methods lack precision and provide limited insights into actual stockpile volumes. Backfilling calculations also rely on manual data, leading to inefficiencies and potential errors. Despite these challenges, volume tracking remains essential for operational success, requiring significant human effort and resources every year. A salt mine in Germany relies on regular surveys to maintain an accurate inventory of materials stored in its chambers. These monthly surveys require one day of climbing and measuring, followed by another day of data analysis—totaling two days per month. Surveyors climb the salt cones to measure height from the top to the ceiling, then use CAD software to calculate volumes. This method is physically demanding, time-consuming, and prone to inaccuracies. With such limitations, the mine sought a more efficient and safer solution to improve their stockpile measurement process. Engineers at the mine learned about the Elios 3, a compact indoor drone equipped with LiDAR and Flyability’s SLAM engine, FlyAware. This technology allows real-time 3D mapping, even in tight or complex environments. Given the mine's need for efficiency and safety, they decided to test the Elios 3. Their goal was to replace manual measurements with a faster, more accurate, and safer alternative. The test proved highly successful. Surveyors were able to create detailed 3D maps of the salt stockpiles using the Elios 3, achieving results that were faster, more accurate, and safer than previous methods. “I had never flown a drone before, but the application was very user-friendly. I was flying and collecting data within the same day. It’s stable, easy to handle, and the display is excellent.†– Mining Engineer The survey team was extremely satisfied with the performance of the Elios 3. The results demonstrated clear improvements in speed, accuracy, and safety, making it a strong candidate for future use in all their volume calculations. Adopting the Elios 3 would not only save time and improve data quality, but also enhance safety across the mine. It could also be used to explore unstable areas without putting personnel at risk. Beyond stockpile measurements, the Elios 3 has the potential to transform how the mine operates. The head of the surveying department is already considering using it to create full 3D maps of the entire mine, replacing outdated 2D plans with detailed, accurate representations. WWSC Products,Fast Group In Workshop,Move to Workshop Place,Size and Figure Are Customized Changzhou Fuku Precision Machinery Co., Ltd. , https://www.fukuindustrial.comElios 3 Enhances Safety and Precision in Salt Mine Stockpile Measurements

Key Advantages at a Glance

Introduction

Customer Needs

Solution

Results

Conclusion