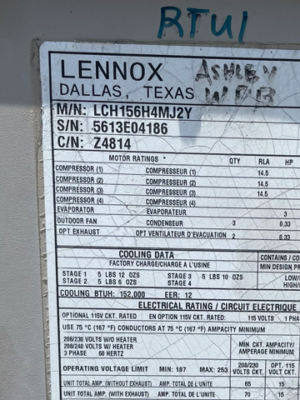

Say goodbye to the common leaks and maintenance headaches of Lennox’s LCH156H4 rooftop unit with a smart, cost-effective microchannel conversion. When it comes to replacing commercial condenser coils, the Lennox LCH156H4 is one of the most commonly encountered units. It's known for its efficiency, but also for some persistent issues — especially when it comes to its all-aluminum microchannel coils. Many technicians face challenges when dealing with these coils, which are often prone to leaks and difficult to repair. That’s why many choose to convert them to copper tube, aluminum fin coils — a more reliable and long-lasting solution. Microchannel coils have been widely used in HVAC systems for years, not just in Lennox units but across the industry. They offer lower material costs and reduced refrigerant use, making them an attractive option for manufacturers. However, they come with their own set of drawbacks that can impact performance and maintenance over time. The Challenges of Microchannel Coils One of the main issues with microchannel coils is that they tend to accumulate dirt quickly, leading to poor heat transfer and increased system pressure. This can result in higher energy consumption and potential equipment failure if not addressed regularly. Plus, the low refrigerant charge required by these coils makes them sensitive to even small leaks or improper installation. Repairing microchannel coils is also tricky. Aluminum components can be difficult to weld or seal without specialized tools and techniques. And because of their design, even minor damage can lead to significant performance issues. Why Switch to Copper Tube, Aluminum Fin Coils? A copper tube, aluminum fin coil offers a more durable and manageable alternative. These coils are easier to maintain and repair, reducing downtime and long-term costs. They also allow for more flexibility during repairs, as the system can be pumped down rather than fully evacuated, saving both time and refrigerant. Additionally, copper tube coils are less prone to leaks at the connections, and their design allows for better refrigerant flow, improving overall system efficiency. What You Need to Know About Circuit Matching When converting from a microchannel coil to a copper tube coil, it's important to match the circuits correctly. If your unit uses multiple coils in parallel, you may need to replace all of them to ensure consistent refrigerant distribution and pressure. Mixing different types of coils can lead to imbalances and operational problems. Expert Help is Always Recommended While the Lennox LCH156H4 is a popular model for microchannel conversions, this upgrade is available for a wide range of commercial HVAC units. With years of experience and thousands of successful conversions under our belt, Nationwide Coils has earned the reputation as the go-to experts in microchannel coil upgrades. If you're looking to improve the reliability and efficiency of your HVAC system, contact us today. Whether you call 1-888-CoilPro or email us, we’re here to help. Just provide the make and model of your unit, and we’ll get started on the best solution for you. Japanese Series Wash Pump,Windscreen Wash Pump,Water Pump Windshield Washer,Rear Washer Pump ruian city yixuan auto parts co.,ltd , https://www.yixuanauto.comUpgrading the Microchannel Coil in the Lennox® LCH156H4: Boost Performance and Longevity