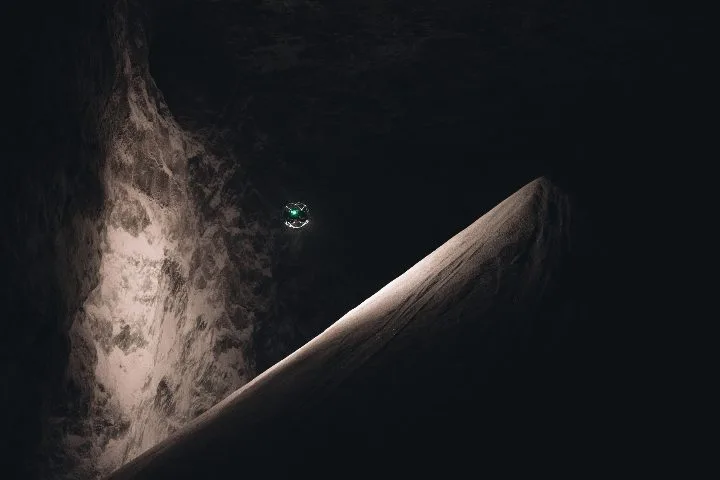

At a salt mine in Germany, mining engineers used LiDAR data from the Elios 3 to measure stockpiles more safely and accurately than ever before. Speed Measuring large salt stockpiles manually is time-consuming and inefficient. The Elios 3 streamlines this process by allowing surveyors to remain on the ground while flying the drone through the area, generating accurate 3D models of the stored material quickly. Accuracy The Elios 3 provides highly accurate 3D models, offering a level of precision that manual methods cannot match. This ensures better volume calculations and more reliable data for decision-making. Safety Traditional methods require surveyors to climb unstable salt piles, which can be dangerous. The Elios 3 eliminates this risk by enabling remote data collection, keeping workers safe on the ground while still gathering all necessary information. Volume measurements are a crucial part of operations in mining and aggregate industries, where large quantities of materials are stored over long periods. These measurements help track inventory, plan backfilling, and manage resources effectively. Traditionally, surveyors have relied on manual methods, such as climbing stockpiles or using handheld sensors, which are not only slow but also prone to errors. These techniques can be dangerous and lead to inaccurate results, making it difficult to maintain an exact understanding of material volumes. This challenge has led many mines to invest significant time and resources into manual processes, despite knowing the limitations of the data they produce. A salt mine in Germany faced these same challenges. Their survey team was responsible for mapping the entire mine and maintaining an accurate inventory of salt in storage chambers. Monthly surveys were conducted, requiring one full day for manual data collection and another for analysis. Surveyors would climb the salt cones to measure their height and then use CAD software to calculate the volume. This method was physically demanding, time-consuming, and often led to inaccuracies in the final results. Recognizing the need for a safer and more efficient solution, the team explored new technologies that could improve their workflow without compromising accuracy or safety. Engineers and surveyors at the mine learned about the Elios 3, a compact indoor drone equipped with a LiDAR sensor and powered by Flyability’s FlyAware SLAM technology. This allowed real-time 3D mapping during flights, making it ideal for challenging environments like underground mines. Given the success of previous Flyability drones in similar settings, the team decided to test the Elios 3 for their stockpile measurements. They hoped it would streamline the process, reduce risks, and provide more accurate data for their operations. By using the Elios 3, they aimed to eliminate the need for physical climbs, speed up data collection, and ensure more precise volume calculations. The test with the Elios 3 was a resounding success. Surveyors were able to generate high-quality 3D models of multiple salt stockpiles within the mine, demonstrating the effectiveness of the technology. Here's what the team found: Speed. Using the LiDAR sensor, the team collected all necessary data for each stockpile in a fraction of the time it would take with manual methods. Accuracy. The volume calculations based on LiDAR data were significantly more accurate than those obtained through traditional techniques. Safety. By eliminating the need to climb the salt cones, the Elios 3 greatly improved the safety of the operation, allowing surveyors to collect data remotely from the chamber entrance. Stability & Ease of Use. The Elios 3 was easy to fly, even for those with no prior drone experience. One engineer noted that they were able to start collecting data within the same day of receiving the drone. "I had never flown a drone before, but the application was very user-friendly. I got the hang of it quickly. It's stable, comfortable to handle, and the display is excellent," said one mining engineer. Both engineers and surveyors were impressed with the performance of the Elios 3. The success of the trial has led the surveying department to consider adopting the drone for all future volume calculations. Switching to the Elios 3 would save time, improve data quality, and enhance safety across their operations. Additionally, the drone could be used to explore unstable areas, reducing the need for human entry and increasing overall operational efficiency. Beyond stockpile measurements, the Elios 3 has the potential to transform how the mine understands its environment. The head of the surveying department is interested in using the drone to create detailed 3D maps of the entire mine, moving beyond the current 2D plans for more accurate and comprehensive documentation. Metal Welding Parts,Surface,Treatment and Testing,Customization Size Figure Changzhou Fuku Precision Machinery Co., Ltd. , https://www.fukuindustrial.comElios 3 Enhances Safety and Precision in Salt Mine Stockpile Measurements

Key Benefits at a Glance

Introduction

Customer Needs

Solution

Results

Conclusion