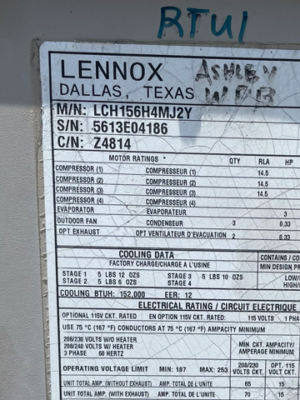

Tired of frequent leaks and maintenance headaches from your Lennox LCH156H4 rooftop unit? A cost-effective microchannel conversion can solve these issues and boost efficiency. When it comes to replacing commercial condenser coils, the Lennox LCH156H4 is often at the top of the list. This popular rooftop unit is known for its performance, but it also comes with some inherent challenges—especially when it comes to the all-aluminum microchannel coil. Many technicians find themselves replacing or converting this coil, typically switching from an aluminum microchannel design to a copper tube and aluminum fin configuration. This upgrade has become a common solution in the HVAC industry over the past decade, not just for Lennox units, but for most OEM equipment as well. While microchannel coils are more affordable and help reduce refrigerant usage, they come with their own set of drawbacks. These coils are prone to dirt buildup, which can lead to increased head pressure and system inefficiencies. They also require precise refrigerant charging, and repairs can be complex and time-consuming due to the nature of aluminum construction. The Drawbacks of Microchannel Coils One major issue with microchannel coils is that they tend to accumulate dirt quickly, especially if maintenance isn’t performed regularly. This can cause operational problems, such as high head pressure and reduced cooling capacity. Additionally, because they hold less refrigerant, any leak can have a significant impact on system performance. Repairing aluminum microchannel coils is also tricky. It often involves using two-part epoxy or even a torch, which can weaken the material further. Plus, the connection points between copper and aluminum are prone to leaks, adding to the long-term maintenance burden. #ChangeTheChannel: Switch to a Copper Tube, Aluminum Fin Coil A copper tube and aluminum fin coil offers a more reliable and durable alternative. This type of coil is easier to repair, maintain, and service, making it a smarter choice for long-term use. One of the key benefits is the ability to pump down the system during repairs, eliminating the need to recover all the refrigerant first. Other advantages include: Why Completing the Circuit Matters If you're replacing a microchannel coil in a unit like the Lennox LCH156H4, it's important to complete the circuit properly. For example, if the unit has four coils per circuit and one fails, you should replace all four to ensure balanced refrigerant flow and avoid system imbalances. The pressure drop characteristics of copper tube coils differ from those of microchannel coils, so mixing them can lead to performance issues. #MastersOfMicrochannelConversion While the Lennox LCH156H4 is a common candidate for microchannel conversion, this upgrade is available for virtually any major commercial HVAC unit. At Nationwide Coils, we’ve completed thousands of conversions over the years, making us experts in this field. If you're looking to improve the performance and longevity of your HVAC system, consider a microchannel conversion. Our team of professionals can guide you through the process and help you choose the best solution for your needs. Call 1-888-CoilPro or email us today. All we need is your unit’s make and model to get started. Windshield Wash Pump,Washer Pump,Screen Wash Pump,Pump For Windshield Washer Fluid ruian city yixuan auto parts co.,ltd , https://www.yixuanauto.comUpgrading the Lennox® LCH156H4: Enhance Performance and Reliability with a Microchannel Conversion