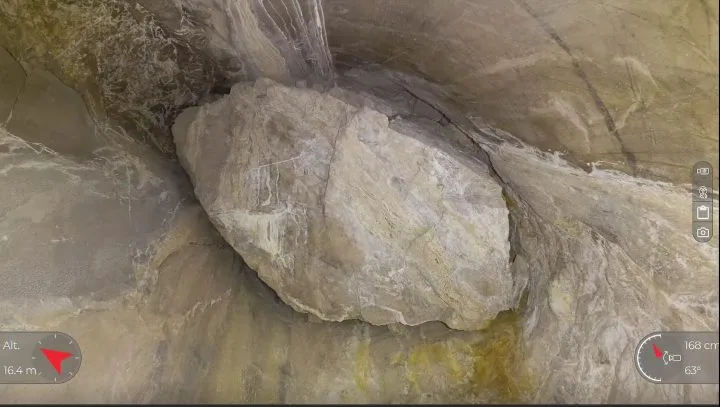

An ore pass is a vertical or inclined shaft used in mining to transport valuable ore and waste rock from one level of the mine to another. These structures are essential for efficient material handling, reducing the need for long hauls between different levels of the mine. By leveraging gravity, ore passes provide a fast and cost-effective way to move materials, improving overall productivity. Ore passes rely on gravity to move materials from higher to lower levels in a mine. There are two primary methods for constructing them: drill and blast, and mechanical excavation using a raise borer. Each method has its own advantages depending on the geological conditions and the scale of the operation. When planning an ore pass, several factors must be taken into account: Watch this video to see footage from Flyability's Elios drone shot inside an ore pass with a hang-up obstructing it:  In the mining industry, there are two main types of ore pass systems: flow-through and full. Both systems are designed to move ore and waste from the mining face to the draw point, where it is loaded onto conveyors, trucks, or rail cars for further processing or transport. The flow-through system is ideal when the ore contains high amounts of fine particles, which can easily cause blockages. In this system, material flows continuously, preventing fines from settling and reducing the risk of hang-ups. This system is also used when broken rock is fed to mills at a faster rate than it is produced underground. However, the constant flow of material makes the ore pass more susceptible to wear and tear, requiring regular maintenance and potential reinforcement. If not properly managed, this can lead to costly downtime and repairs. A full ore pass system maintains a consistent amount of material within the pass at all times. This helps prevent degradation, rock failures, and seismic events. However, because the material isn’t constantly flowing, fines tend to settle, increasing the likelihood of hang-ups. To manage this, draw times are extended to maintain proper material levels. This system is commonly used in mines where stability and safety are critical, though it requires careful monitoring to prevent blockages and operational disruptions. Regular monitoring of ore passes is crucial for maintaining their structural integrity and preventing hazardous situations. It helps detect early signs of wear, blockages, or instability that could lead to serious consequences if ignored. Key elements monitored in an ore pass include: Without proper monitoring, ore passes can become clogged, leading to operational delays, equipment damage, and even danger to miners. Regular inspections help prevent these issues and ensure safe and efficient operations. A blockage in an ore pass can halt production and create significant safety risks. In 2023, a major mining operation in Colorado faced a severe hang-up that prevented any ore from passing through the system. Initial attempts to locate the blockage using traditional methods were unsuccessful, leading to months of wasted effort and eventual abandonment of the area. Eventually, the team turned to the Elios 3 drone, which provided real-time visual feedback and a 3D live model of the ore pass. Within minutes, the drone identified the exact location of the blockage, allowing for targeted and effective resolution. Within ten minutes, geolocational data on the Elios 3’s 3D Live Map showed them exactly where the clog was located in the raise. You can learn more about how they used the data from the Elios 3 survey to investigate and deal with the ore pass hangup. Three Seats Electric Car,Electric Tricycle For Elderly,Low Speed Car,Electric Vehicles YUMBOMOBILITY LTD , https://www.yumbomobility.comWhat is an Ore Pass in Mining?

Considerations for Building an Ore Pass

Types of Ore Pass Systems

Flow-Through Ore Pass System

Full Ore Pass System

A hang-up in an ore pass

A hang-up in an ore passOre Pass Monitoring

Monitoring the material level in an ore pass

Using Drones to Investigate Ore Pass Blockages