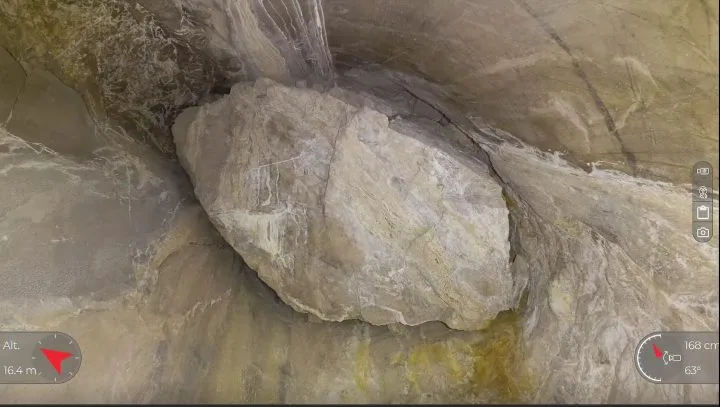

An ore pass is a critical component of underground mining operations, designed to transport valuable ore and waste rock from one level of the mine to another. These vertical or inclined shafts help reduce the need for long hauls between different levels, making material movement more efficient and cost-effective. Ore passes are typically constructed using either the drill and blast method or mechanical excavation techniques like raise boring. The choice of method depends on the geology, depth, and overall layout of the mine. Proper planning ensures that the ore pass remains functional and safe over time. When designing an ore pass, several factors must be taken into account: Watch this video to see footage from Flyability's Elios drone shot inside an ore pass with a hang-up obstructing it:  There are two main types of ore pass systems used in mining: flow-through and full systems. Both are designed to move ore and waste to a draw point, where it is then loaded onto conveyors, trucks, or rail cars. In a flow-through system, material flows continuously through the ore pass, reducing the risk of blockages caused by fine particles settling. This system is ideal when the ore contains a lot of fines or when the mill requires a steady supply of material. However, the constant flow can lead to increased wear and maintenance needs. A full ore pass system maintains a consistent amount of material within the pass, which helps prevent rock failures and seismic activity. However, this also increases the likelihood of hang-ups due to material settling. Careful management of draw times is essential to keep the system running smoothly. Regular monitoring of ore passes is essential to maintain their structural integrity, prevent seismic events, and avoid overfilling. Key elements monitored include material levels, wall conditions, liner quality, and equipment functionality. Without proper monitoring, blockages can occur, leading to operational delays, equipment damage, and even safety risks for miners. Drones have become a game-changer in inspecting these hard-to-reach areas quickly and safely. Blockages in ore passes can bring mining operations to a standstill. In 2023, a major mining operation in Colorado faced a severe hang-up that blocked the entire passage. Initial attempts to locate the clog using scanners and cameras were unsuccessful, leading to months of downtime and eventual abandonment of the area. The solution came in the form of the Elios 3 drone, which provided real-time visual and 3D mapping data. Within minutes, the team was able to pinpoint the exact location of the blockage and take action. This case highlights how modern technology can solve complex mining challenges efficiently and safely. Within ten minutes, geolocational data on the Elios 3’s 3D Live Map showed them exactly where the clog was located in the raise. You can learn more about how they used the data from the Elios 3 survey to investigate and deal with the ore pass hangup. Cabin Scooter W/O Doors,Eec Cabin Scooter,Waterproof And Rainproof Cabin Scooter,Electric Cabin Tricycle With Roof Canopy YUMBOMOBILITY LTD , https://www.yumbomobility.comWhat is an Ore Pass in Mining?

Key Considerations When Building an Ore Pass

Types of Ore Pass Systems

Flow-Through Ore Pass System

Full Ore Pass System

A hang-up in an ore pass

A hang-up in an ore passOre Pass Monitoring

Monitoring the material level in an ore passUsing Drones to Investigate Ore Pass Blockages