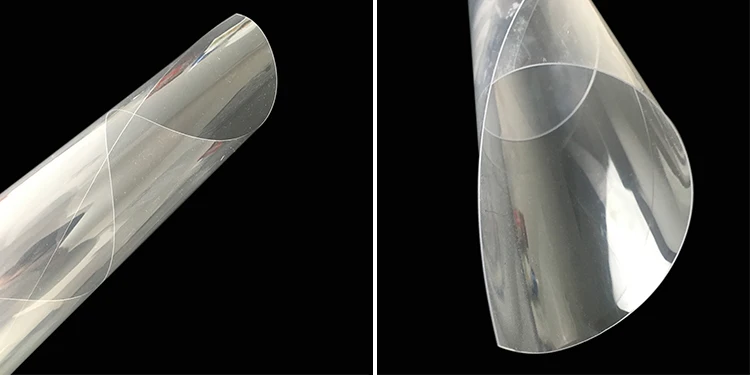

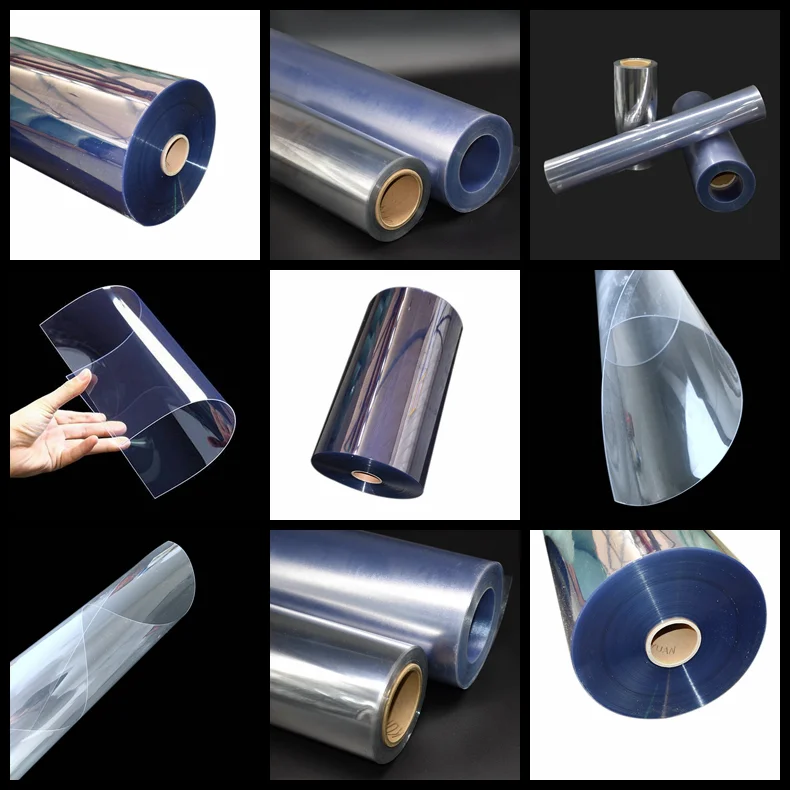

We are one of the bigest pharmaceutical PVC sheet supplier in China for supply our best product pharmaceutical PVC sheet with the reasonable price plastic food packaging PVC Film Food Blister Packaging Clear Rigid PVC Vacuum Forming Sheet is most commonly used for plastic moldings where it is injected into a mold while molten, forming complex shapes at relatively low cost and high volume, examples include bottle tops, bottles and fittings. It can be used as blister packaging rigid PVC sheets. Product Name RIGID PVC SHEET Thickness 0.20-0.45mm Width 75mm– 1300mm Colors Transparent ,Glass clear ,Clear with blue tint,Amber color ,Orange color ,White color Blue color ,Brown color ,Pink color ,Green color Transparency Transparent,semi-transparency,opaque Application Pharmaceutical tablets, Pack capsules ,Medicine pills, Injection tray,blister packaging Surface Bright and Clean Form by roll Hardness Rigid Net weight 10kgs/roll (width 130mm) 20kgs/roll or 25kgs/roll(width 250mm) Outer diameter 200-700mm Pvc Transparent Sheet,Rigid Pvc Transparent Plastic,Pvc Sheet For Food Packaging,Plastic Pvc Sheet For Food Packaging Shandong Top Leader Plastic Packing CO., LTD , https://www.sdzlplastic.com

Material

PVC

Color

Clear

Width

200-700mm

Thickness

0.1-0.8mm

Grade

virgin raw material

Usage

PVC sheet can be applied to the blistering, folding, packing, printing of tools, fishing gear, toys, electronics, garments and other industries.

NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY was established in 2001. We specialize in high-precision CNC machining and offer a wide range of manufacturing services, including pressure casting, sand casting, investment casting, gravity casting, and more. Our materials include aluminum alloys such as A380, A390, ADC12, YL102, A356, 6000 series aluminum extrusion, zinc alloy, iron, and copper. Our products are mainly exported to countries like the USA, Europe (UK, Germany, Italy, Belgium), and Asia (Japan, Korea). We have successfully obtained the ISO/TS16949 quality management certification.

Our core capabilities include:

- **Model NO.:** 349

- **Machining Fixture:** Fixture Design and Fabrication

- **Software Applied:** PRO/E, AutoCAD, SolidWorks 2013, UG

- **Trademark:** Customized

- **Transport Package:** Carton, Environmental Pallet

- **Specification:** Customized

- **Origin:** Ningbo

- **HS Code:** 7616991090

**Material:** ADC-12

**Cavity Number:** 1

**Process Technology:** High Pressure Die Casting

**Product Dimensions:** Customized

**Casting General Tolerance:** Grade GB-CT4

**Surface Finish:** Polishing, Vibratory Deburring, Anodizing, Powder Coating, Painting, etc.

**Flow Processes:** Die Casting, Degating, Polishing, Vibratory Deburring, Machining, CNC Machining by Machining Center, Cleaning, Powder Coating, Packing, Shipping

**Control Measures:** Incoming Material Test, First Article Inspection, Routing Inspection, Final Item Inspection, and Outgoing Quality Control

**Inspection Equipment:** CMM, Caliper, Plug Gage, Spectrograph, Pneumatic Measuring Tool, etc.

**Application:** Machinery Parts

**Certificate:** ISO/TS16949:2009

**Lead Time:** 30-35 days

**Trade Term:** FOB Ningbo

**FAQ:**

**Q1. When can I get the price?**

A: We usually quote within 2-3 days after receiving your RFQ or provide feedback within 2 days if there are any questions on the drawings that need confirmation.

**Q2. How long is the lead-time for mold?**

A: It depends on the size and complexity of the mold. Normally, the lead time is 35-45 days.

**Q3. I have no 3D drawing, how should I start the new project?**

A: You can supply us with a sample, and we will help you create a 3D model accordingly.

**Q4. Before shipment, how to ensure the product quality?**

A: We follow strict development procedures. During sample development, we can produce according to PPA, and once PSW is approved, we ensure quality control throughout the process.

We are committed to delivering high-quality products and providing excellent customer service. Whether you need custom parts, tooling, or full production support, we are here to help. Contact us today for a detailed quote and further discussion.

Product Description

Product Application

Product Process